Low Power Min (Short) Termination

The Dolph Microwave Low Power Min (Short) Termination is a precision-engineered RF waveguide dummy load designed to protect sensitive transmitter components (BUC, HPA, TWTA, SSPB) during testing. Providing an exceptional 1.2:1 VSWR match from 1.13 GHz to 40 GHz across waveguide sizes WR650 to WR28, its robust copper construction with gold-plated brass flanges and IP65-rated enclosure ensures reliable, high-performance signal absorption and system protection in demanding environments like satellite communications, radar, and wireless base stations.

Product Description:

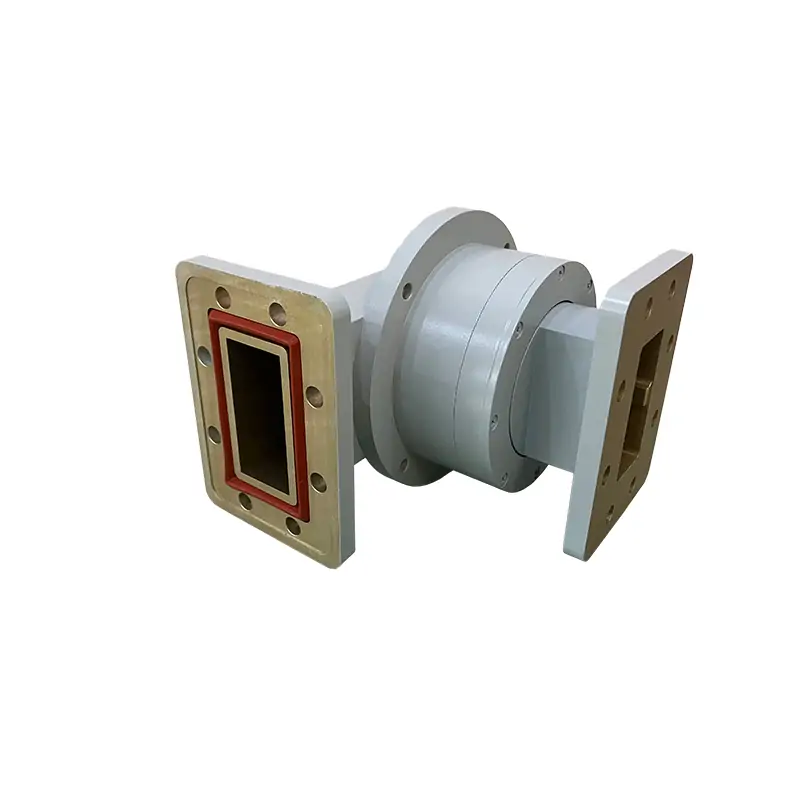

Dolph Microwave’s Low Power Min (Short) Termination is a precision RF waveguide dummy load designed to provide a high-performance, matched impedance termination for frequencies spanning 1.13 GHz to 500 GHz (across various models). This essential test and measurement component replaces the antenna during RF system verification, safeguarding critical transmitter elements like BUCs, HPAs, TWTAs, and SSPBs from damage caused by reflected power.

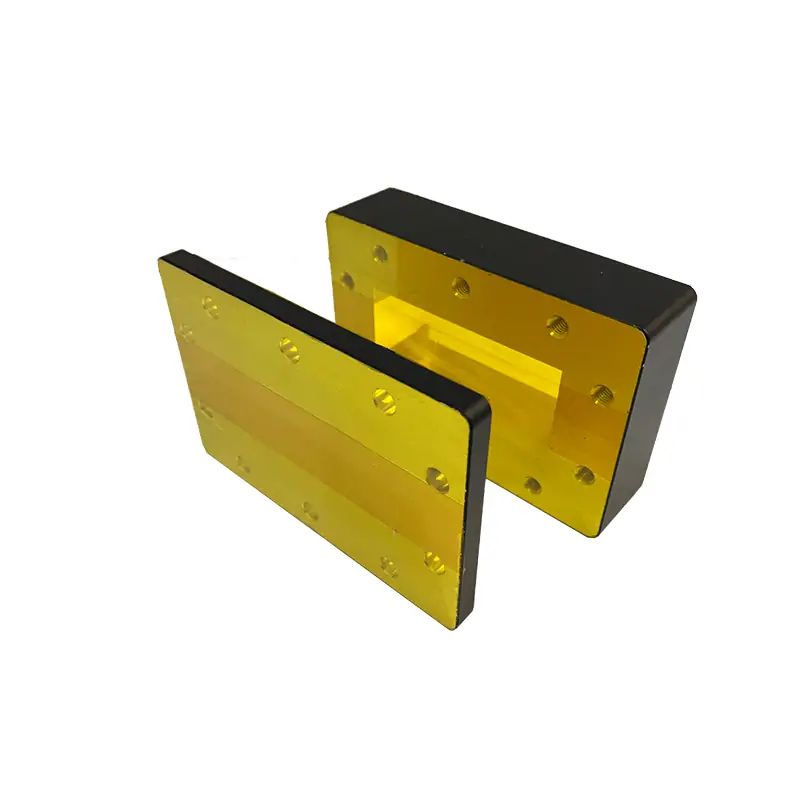

Engineered for reliability in demanding environments, each unit features a short waveguide section integrated with a precisely tapered dielectric load for optimal RF energy absorption. Constructed from copper waveguide with brass flanges, gold-plated contact surfaces ensure excellent conductivity and corrosion resistance. Standard models offer an impressive voltage standing wave ratio (VSWR) of 1.2:1 across their full specified waveguide bandwidth (WR650 to WR28), with lengths starting from just 20mm for high-frequency variants.

Key Features & Benefits:

Superior Impedance Matching: Achieves a consistently low VSWR of 1.2:1 across the entire bandwidth of each waveguide size, ensuring minimal signal reflection for accurate testing.

- Broad Frequency Coverage: Comprehensive range of models supports applications from 1.13 GHz (L-band) up to 500 GHz (sub-millimeter wave).

- Precision Waveguide Design: Utilizes short waveguide sections (160mm to 20mm depending on band) with optimized internal geometry for consistent performance.

- High-Quality Construction: Robust copper waveguide components with brass flanges featuring gold-plated contact surfaces for maximum RF efficiency and long-term reliability.

- Tapered Dielectric Load: Specifically engineered internal load geometry provides efficient broadband RF energy absorption.

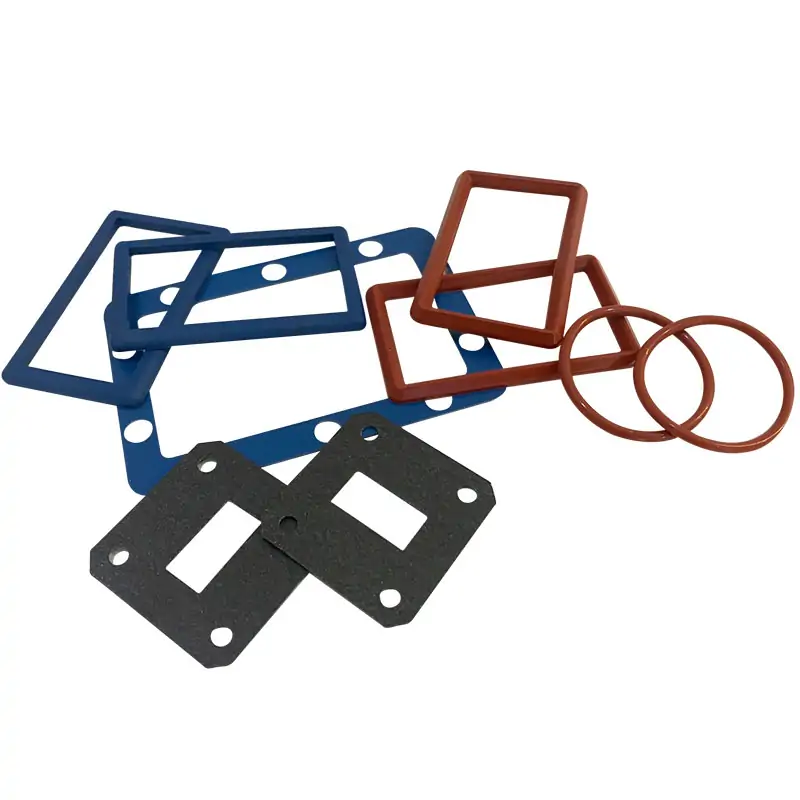

- Environmental Protection: Standard IP65 rating (dust-tight and protected against low-pressure water jets) for reliable operation in various settings.

- Durable Finish: Features Surtec corrosion protection treatment (chromate conversion) and a standard flat black paint finish, with custom options available.

- Ideal for Systems Integration: The compact “Min” profile (especially shorter units like DH-320WMPL at 20mm) makes it suitable for integration into test benches and systems where space is limited.

Primary Applications:

This precision termination is critical for numerous RF applications:

- Testing and Measurement: Essential lab tool for characterizing transmitters, amplifiers (BUCs, HPAs, TWTAs, SSPBs), antennas, and other RF components without radiating signals.

- Communication Systems: Verification and maintenance of radar systems, satellite communication ground stations (protecting sensitive uplink amplifiers), wireless communication base stations (including 5G infrastructure).

- R&D and Manufacturing: Used extensively in development, prototyping, calibration, and production testing phases across telecommunications, aerospace, and defense sectors.

| MODEL | FREQUENCY RANGE(GHz) | WG SIZE | VSWR | POWER RATING CW (W) | FLANGES TYPE | LENGTH (mm) | INGRESS PROTECTION | MATERIAL | FINISH | DATASHEET | ||

| COVER | GROOVED | |||||||||||

| DH-14WMPL… | 1.13-1.73 | WR650 | 1.2:1 | 2~50 | UDR14 | PDR14 | 160 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-18WMPL… | 1.45-2.2 | WR510 | 1.2:1 | 2~50 | UDR18 | PDR18 | 160 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-22WMPL… | 1.72-2.61 | WR430 | 1.2:1 | 2~50 | UDR22 | PDR22 | 145 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-26WMPL… | 2.17-3.3 | WR340 | 1.2:1 | 2~50 | UDR26 | PDR26 | 120 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-32WMPL… | 2.6-3.95 | WR284 | 1.2:1 | 2~50 | UDR32 | PDR32 | 100 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-40WMPL… | 3.22-4.9 | WR229 | 1.2:1 | 2~50 | UDR40 | PDR40 | 80 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-48WMPL… | 3.94-5.99 | WR187 | 1.2:1 | 2~50 | UDR48 | PDR48 | 55 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-58WMPL… | 4.64-7.05 | WR159 | 1.2:1 | 2~50 | UDR58 | PDR58 | 50 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-70WMPL… | 5.38-8.17 | WR137 | 1.2:1 | 2~30 | UDR70 | PDR70 | 45 | IP65 | Al/Cu | Chromate/Painted | STEP | |

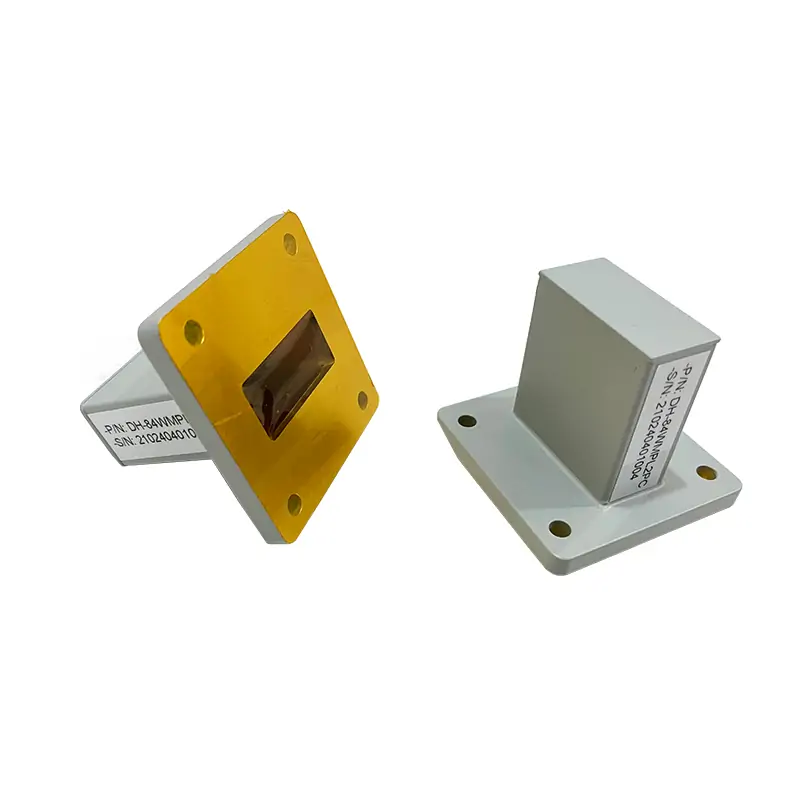

| DH-84WMPL… | 6.57-9.99 | WR112 | 1.2:1 | 2~30 | UDR84/UBR84 | PDR84/PBR84 | 40 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-100WMPL… | 8.2-12.5 | WR90 | 1.2:1 | 2~20 | UDR100/UBR100 | PDR100/PBR100 | 40 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-120WMPL… | 9.84-15 | WR75 | 1.2:1 | 2~20 | UBR120 | PBR120 | 35 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-140WMPL… | 11.9-18 | WR62 | 1.2:1 | 2~20 | UBR140 | PBR140 | 30 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-180WMPL… | 14.5-22 | WR51 | 1.2:1 | 2~20 | UBR180 | PBR180 | 30 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-220WMPL… | 17.6-26.7 | WR42 | 1.2:1 | 2~15 | UBR220 | PBR220 | 30 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-260WMPL… | 21.7-33 | WR34 | 1.2:1 | 2~15 | UBR260 | PBR260 | 20 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| DH-320WMPL… | 26.3-40 | WR28 | 1.2:1 | 2~15 | UBR320 | PBR320 | 20 | IP65 | Al/Cu | Chromate/Painted | STEP | |

| Part Number Guide: DH-100WMPL20PA "100"—Waveguide Size | WR90 "WMPL"—Waveguide Type | Precision Low Power Min. (Short) Loads "20"— Power Rating | 20 W "P"— Flange Type | Rectangular Flat "M"— Flange Type | Rectangular Grooved "A/C"— Material | Aluminium, Cu |

||||||||||||

| Note: All Dolph-MW models include an surtec/corrosion protection treatment and are painted flat black. Flanges are unplated, polished and surtec. Other finishes and paint colors are available upon request. |

||||||||||||