High Power Water-Cooled Loads

Dolph Microwave High Power Water-Cooled Waveguide Loads provide unmatched termination for demanding RF systems, reliably handling up to 150 kW average power with exceptional heat dissipation via integral water cooling. Engineered with ultra-high temperature refractory ceramic absorbers within robust welded aluminum housings and compliant with MIL-D-3954, they ensure safety, low VSWR (≤1.2:1), and critical system protection.

Product Introduction:

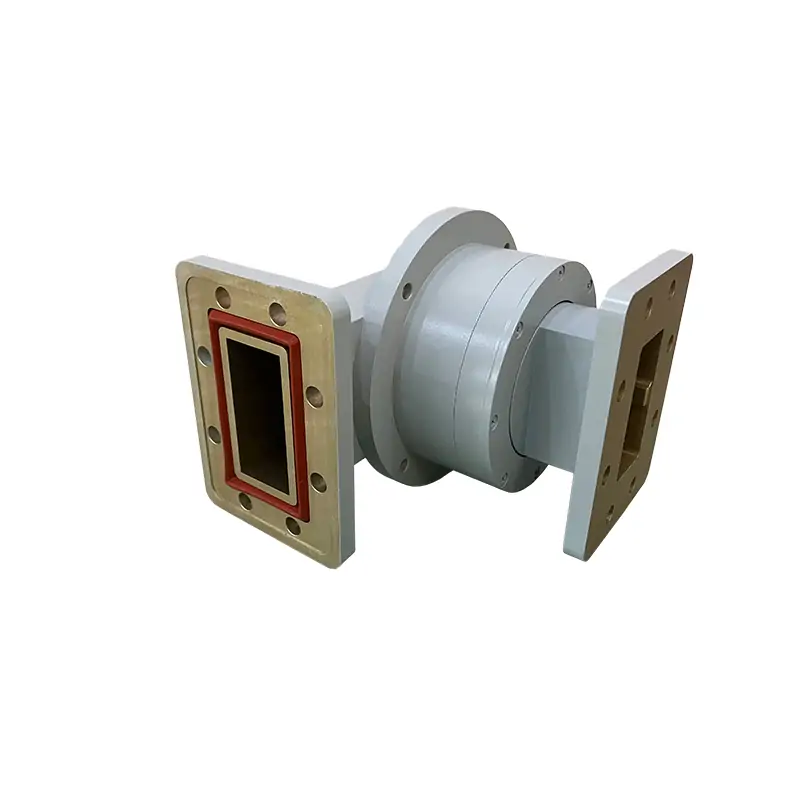

Dolph Microwave High Power Water-Cooled Waveguide Loads are engineered microwave termination solutions designed for demanding applications requiring exceptional power handling and heat dissipation. Utilizing internal water circulation, these loads reliably absorb and dissipate high levels of RF/microwave energy (up to 150 kW average power) to protect sensitive components.

Constructed with ultra-high temperature refractory ceramic absorbers housed within robust welded aluminum structures, they deliver unmatched durability and thermal efficiency. Manufactured to MIL-D-3954 standards, Dolph loads provide consistent VSWR performance ≤ 1.2:1 across specified waveguide bands from WR975 down to WR28.

Key Features and Benefits:

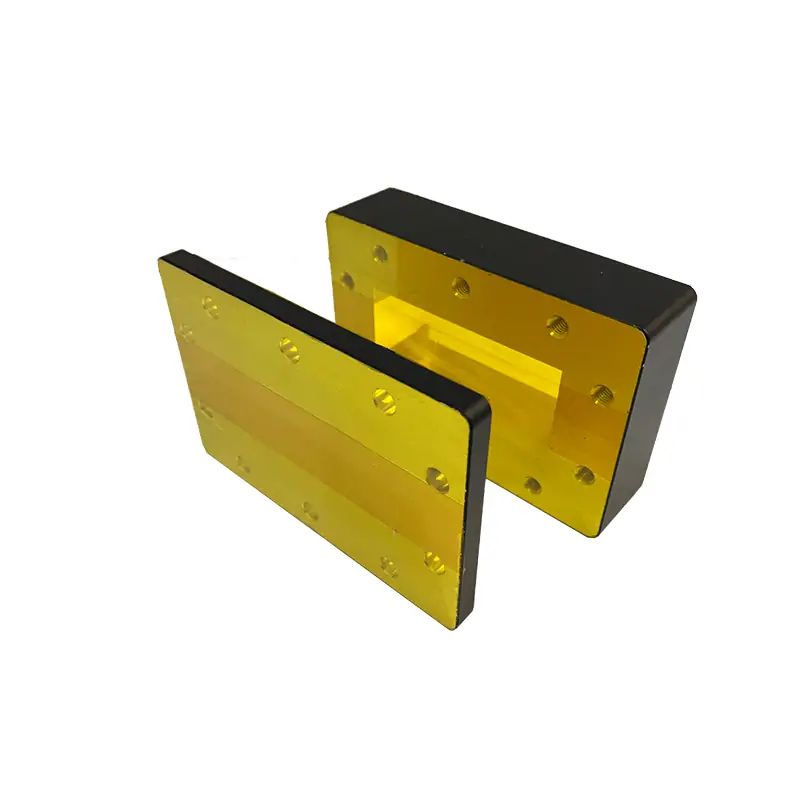

Dolph Microwave water-cooled waveguide loads excel through a combination of robust engineering and optimized thermal management. Central to their performance is an ultra-high temperature refractory ceramic microwave absorber, ensuring stable absorption characteristics even under intense thermal loads.

This critical component is housed within a precision welded aluminum structure, designed to maximize thermal conductivity and cooling efficiency while maintaining excellent mechanical strength. Internal water flow provides exceptional heat dissipation capabilities, significantly enhancing average power handling (up to 150 kW) far beyond air-cooled alternatives, resulting in a very low cost per kilowatt.

The design includes an integrated fine matcher at the input for optimal impedance matching, minimizing reflected power. Cooling interfaces feature standardized Push-in fitting QS or NPT connections for reliable coolant integration. All materials contacting the coolant are rigorously selected for safety and compatibility.

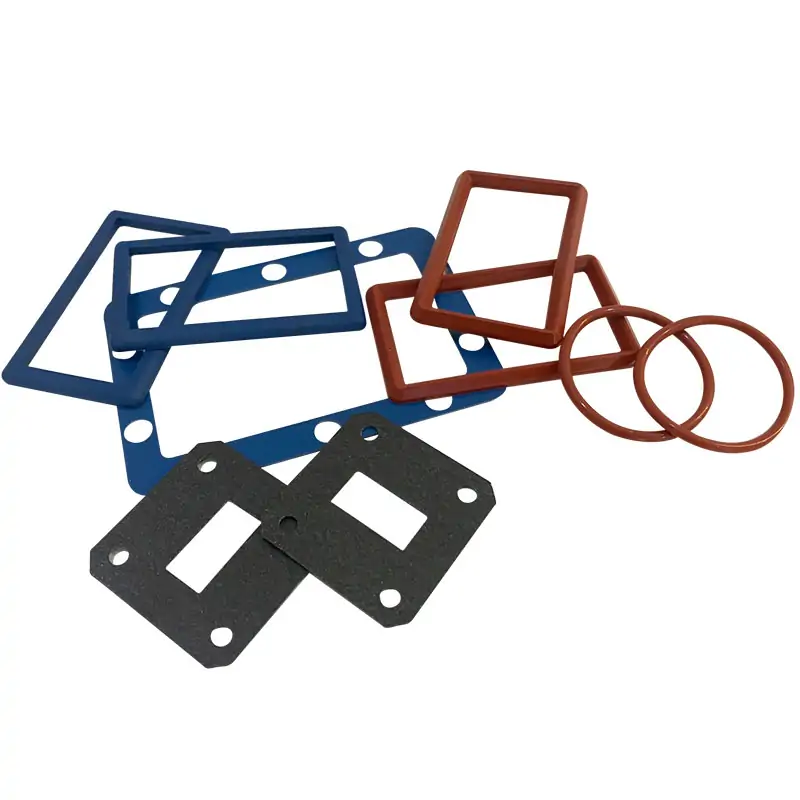

The Silicone-based Pyromark 1200 flat black coating ensures superior thermal radiation and protection. Compliant with MIL-D-3954, these loads meet stringent military-grade performance specifications. Optional corrosion protection (Surtec) and polished flanges are standard, with custom finishes available upon request.

Primary Applications:

These water-cooled loads are indispensable in environments demanding termination of high RF power. Critical uses include high-power RF system protection where absorbing transmitter energy is essential for safety and equipment longevity.

They are widely utilized in advanced research and high-energy physics devices such as particle accelerators and plasma heating systems. Industrial microwave equipment relying on consistent, high-power sources for processing also depends on these robust terminations.

Additionally, they serve a vital role in test and measurement setups for amplifiers, transmitters, and microwave sources, where accurate, low-VSWR loading is required to validate performance under operational conditions.

| MODEL | FREQUENCY RANGE (GHz) | WG SIZE | VSWR Max. | POWER RATING CW (KW) | COOLING METHOD | INLET WATER TEMP | OUTPUT WATER TEMP | WATER VALVES CONNECTOR | WATER TUBING O.D. (mm) | FLANGES TYPE | MATERIAL | DATASHEET | |

| COVER | |||||||||||||

| DH-9WWHPL… | 0.76-1.15 | WR975 | 1.2:1 | 50~150 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UDR9 | Al | STEP | |

| DH-12WWHPL… | 0.96-1.46 | WR770 | 1.2:1 | 50~150 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UDR12 | Al | STEP | |

| DH-14WWHPL… | 1.13-1.73 | WR650 | 1.2:1 | 50~150 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UDR14 | Al | STEP | |

| DH-22WWHPL… | 1.72-2.61 | WR430 | 1.2:1 | 10~60 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UDR22 | Al | STEP | |

| DH-26WWHPL… | 2.17-3.3 | WR340 | 1.2:1 | 10~50 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UDR26 | Al | STEP | |

| DH-32WWHPL… | 2.6-3.95 | WR284 | 1.2:1 | 3~12 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UDR32 | Al | STEP | |

| DH-40WWHPL… | 3.22-4.9 | WR229 | 1.2:1 | 3~12 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UDR40 | Al | STEP | |

| DH-48WWHPL… | 3.94-5.99 | WR187 | 1.2:1 | 3~12 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UDR48 | Al | STEP | |

| DH-58WWHPL… | 4.64-7.05 | WR159 | 1.2:1 | 3~10 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UDR58 | Al | STEP | |

| DH-70WWHPL… | 5.38-8.17 | WR137 | 1.2:1 | 1~10 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UDR70 | Al | STEP | |

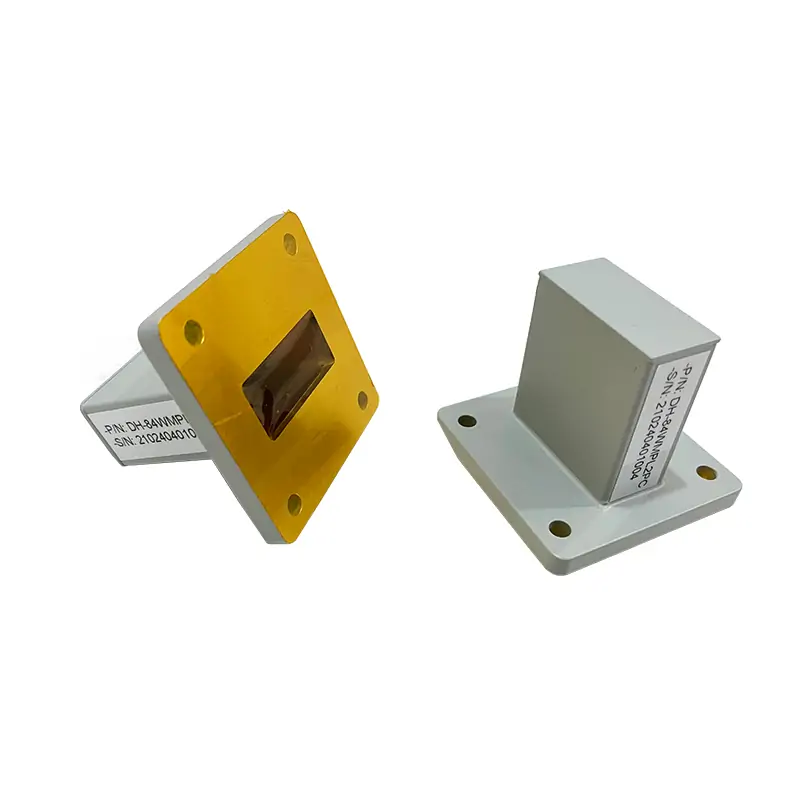

| DH-84WWHPL… | 6.57-9.99 | WR112 | 1.2:1 | 1~10 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UDR84/UBR84 | Al | STEP | |

| DH-100WWHPL… | 8.2-12.5 | WR90 | 1.2:1 | 1~10 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UDR100/UBR100 | Al | STEP | |

| DH-120WWHPL… | 9.84-15 | WR75 | 1.2:1 | 1~10 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UBR120 | Al | STEP | |

| DH-140WWHPL… | 11.9-18 | WR62 | 1.2:1 | 0.5-5 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UBR140 | Al | STEP | |

| DH-180WWHPL… | 14.5-22 | WR51 | 1.2:1 | 0.5-5 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UBR180 | Al | STEP | |

| DH-220WWHPL… | 17.6-26.7 | WR42 | 1.2:1 | 0.5-5 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UBR220 | Al | STEP | |

| DH-260WWHPL… | 21.7-33 | WR34 | 1.2:1 | 0.5-5 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UBR260 | Al | STEP | |

| DH-320WWHPL… | 26.3-40 | WR28 | 1.2:1 | 0.5-5 | Water Cooled | 15°C to 40°C | 85°C | Push-In Fitting QS | 10, 12, 16 | UBR320 | Al | STEP | |

| Part Number Guide: DH-100WWHPL5000PA "100"—Waveguide Size | WR90 "WWHPL"—Waveguide Type | High Power Water-Cooled Loads "5000"— Power Rating | 5000 W CW. "P"— Flange Type | Rectangular Flat "M"— Flange Type | Rectangular Grooved "A/C"— Material | Aluminium, Cu |

|||||||||||||

| Note: All Dolph-MW models include an surtec/corrosion protection treatment and are painted flat black. Flanges are unplated, polished and surtec. Other finishes and paint colors are available upon request. |

|||||||||||||