Table of Contents

Flange Alignment Techniques

During APSTAR-6D satellite commissioning last year, ground stations detected 1.8dB EIRP drop – Keysight N5291A VNA captured VSWR curves showing 0.03mm axial misalignment in WR-42 flanges. Per MIL-STD-188-164A 4.3.9, this causes mode purity factor to fall below threshold, generating X-band spurious harmonics.

Our team developed “tactile feedback calibration” for MUOS satellites: freeze flanges to 77K (achieving 99.7% stainless steel contraction), then use dial indicator probes against waveguide walls. When readings stabilize within ±0.005mm, immediately fill gaps with indium-copper alloy – this controls phase consistency within 0.3°.

- Essential toolkit: Mitutoyo 543-901B dial indicator (0.001mm resolution), Krytox GPL 226 vacuum grease (NASA-STD-6012C compliant), aluminum nitride shims

- Deadly angles: Tighten flange bolts diagonally in three stages – initial torque 1.2N·m (preventing stress deformation), final 3.6N·m monitored by Flir A655sc thermal camera

| Error Type | Military Solution | Industrial Solution |

|---|---|---|

| Axial Misalignment | Laser interferometer real-time correction | Visual inspection + feeler gauge |

| Parallelism | Dual-frequency laser alignment (<0.001°) | Spirit level + protractor (±0.1°) |

| Surface Contamination | Class 100 cleanroom + plasma cleaning | Lint-free wipes |

Testing Pasternack PE42FL500 flanges revealed 0.15dB insertion loss fluctuation at 10-12GHz – teardown showed 3μm machining burrs in O-ring grooves. Per ECSS-Q-ST-70C 6.4.1, such defects cause helium leakage exceeding limits, equivalent to losing $450/hour in coolant.

Pro tip: For Brewster angle incidence issues, apply 0.1mm conductive epoxy (H20E, tanδ=0.002) on flange surfaces. This improved Chinasat-16 Ka-band feed return loss from -18dB to -32dB.

Mind waveguide skin depth – at 94GHz, copper’s skin depth is just 0.21μm. Surface roughness Ra exceeding 0.4μm (λ/500) causes excess loss. Diamond turning (Moore Nanotech 350FG) achieves mirror finishes, boosting power handling by 37%.

Bolt Tightening Sequence

3AM alert from Arizona ground station: Sinosat-6 attitude anomaly, telemetry showing C-band feed VSWR spiking to 2.1. Investigation revealed WR-229 flange bolt fracture causing vacuum leak, triggering ITSO forced shutdown. Having designed Tiantong-1 phased array feeds, I’ve handled 12 similar failures – here’s military-grade bolt tightening details.

▌Case Study: JCSAT-18’s 2019 EIRP drop (1.8dB) from flange bolt torque variation (>18%) cost Intelsat $2.3M FCC fine. MIL-PRF-55342G 4.3.2.1 requires ±5% torque accuracy for military flanges.

- Preload gap elimination: Use Wiha torque screwdriver for 20% nominal torque (e.g. 1.2N·m for M5 bolts) in diagonal sequence. This removes micron-level gaps from flatness deviation, preventing λ/20 phase errors at 28GHz

- Cross-incremental tightening: Three star-pattern stages to final torque (e.g. 2N·m→4N·m→6N·m). Data shows asymmetric loading causes 0.03mm flange warpage, affecting WR-90 Ku-band cutoff frequency

- Plasma cleaning: Ar/O₂ mix (8:2) removes organic contaminants. Mitsubishi Electric 2022 tests proved untreated surfaces release gas molecules in vacuum (<10⁻⁶ Torr), raising waveguide pressure 1000×

| Key Parameter | Civil Standard | Mil-Spec | Failure Threshold |

|---|---|---|---|

| Torque Variation | ≤15% | ≤5% | >20% seal failure |

| Surface Roughness Ra | 1.6μm | 0.8μm | >3.2μm multimode resonance |

For cold welding issues, NASA JPL recommends liquid nitrogen cooling to -196℃, exploiting aluminum/brass CTE difference (23.1 vs. 19.5 μm/m·℃) to release stress. This saved Curiosity rover’s X-band transmitter $4.5M in 2017.

During tightening, Fluke TiX580 thermal cameras detect >8℃ bolt temperature rise – indicating plastic deformation. Remember: at THz frequencies (>300GHz), 0.1μm displacement crashes transmission by 40%, far exceeding bolt failure costs.

Hermeticity Testing

Last month we handled AsiaSat 6D’s waveguide vacuum seal failure – the satellite team dragged me out of bed at 3AM when vacuum levels suddenly jumped from 10-6 Pa to 10-3 Pa, triggering GEO attitude control alarms. Per MIL-STD-188-164A, this leak rate could’ve destroyed the entire Ku-band transponder.

Real military-grade hermeticity testing requires three stages:

- Helium Mass Spectrometer Leak Detection: Soak waveguide assemblies in 5atm helium for 48 hours using INFICON LDS3000, keeping leak rates below 1×10-9 cc/sec. ChinaSat 9B lost $8.6M because a WR-42 flange skipped this step, forcing 2000 extra vacuum pump hours in orbit

- Thermal Shock Cycling: 20 cycles between -55℃ to +125℃ at 8℃/min (per ECSS-Q-ST-70-07C). A Starlink supplier failed when aluminum-silver plating bubbled on cycle #3, causing 0.25dB/m insertion loss

- Micrometeoroid Simulation: Bombard surfaces with 5-50μm aluminum particles at 8km/s. Untreated silicon carbide waveguides get shredded in 15 minutes

NASA JPL’s new trick: Inject Fluorinert fluid into waveguides and film nanoscale vibrations with high-speed cameras. This catches nano-leakage invisible to conventional methods – capillary action creates characteristic tremor frequencies at leak points.

| Method | Sensitivity | Duration | Fatal Flaw |

|---|---|---|---|

| Pressure Decay | 10-4 cc/sec | 2 hours | Can’t distinguish leaks from thermal drift |

| Helium Sniffer | 10-7 cc/sec | 6 hours | Affected by ambient helium |

| Radioactive Tracer | 10-12 cc/sec | 72 hours | Requires NSN license |

At Zhuhai Airshow, we saw waveguides passing ambient tests but leaking in vacuum chambers. Teardown revealed compression set exceeding limits – O-rings worked under atmospheric pressure but failed in vacuum due to insufficient rebound force.

The real nightmare is multi-path leakage – leaks temporarily sealed by flange pressure. Solution: Time-domain reflectometry (TDR) like Keysight D9020AESA sending nanosecond pulses to locate leaks within ±3mm using phase differences.

Terahertz systems demand Ra≤0.1μm surface roughness. During National University of Defense Technology’s acceptance, Zygo interferometry found burrs degrading mode purity factor from 98% to 83% – forcing emergency 5-axis machining.

Grounding Essentials

3AM email from ESA: X-band satellite showed 12dB abnormal loss during vacuum testing. Opened to find connector flange oxidation thick enough for sandpaper. “Who skips grounding in space gear these days?” growled IEEE MTT-S veteran Zhang, welding torch in mouth.

Microwave systems carry EM fields, not currents. NASA JPL proved 0.1μA leakage current causes 0.03° phase drift at 94GHz in vacuum. ChinaSat 9B failed when feed network grounding tabs mismatched thermal expansion coefficients, crashing EIRP.

Military Grounding Protocol (MIL-STD-188-124F 4.3.8):

1. DC Grounding: Beryllium copper springs with <2mΩ contact resistance

2. RF Grounding: λ/4 stub designs

3. Equipotential Bonding: Flexible copper braids for >15℃ thermal gradients

FY-4 upgrade revealed a trap: Domestic waveguide flanges claimed 2μm gold plating but measured 1.3μm. During -180℃~+120℃ cycling, this caused 800% contact resistance spikes. Solution: Eravant military flanges with custom Ag-Ni alloy gaskets.

- Ground loops killed a Ku-band transponder – EMI from TX/RX module loops degraded BER to 10^-3

- Three-point grounding: Both flange ends + support bracket (spacing ≤λ/10)

- Test with VNA TDR mode (e.g. R&S ZVA67 + K103 adapter) finds mm-scale defects

Case study: A remote sensing satellite’s C-band feed developed ground bounce noise. HFSS simulations showed thermal deformation changed λ/4 bolt spacing to 0.27λ, creating resonant cavities. Fixed with Eccosorb AN-74 microwave absorber.

Critical specs:

– Surface roughness Ra<0.8μm (MIL-DTL-83517C)

– Bonding conductor inductance <5nH (Keysight E4990A)

– Galvanic index <0.15V for dissimilar metals

Per ECSS-E-ST-20C, grounding systems must maintain <15% resistance change after 48-hour salt spray tests.

Veteran Wang laser-measures mounting bracket deformation to ensure mechanical stress won’t alter skin depth. In this field, anyone achieving VSWR<1.05 has grounding OCD.

Protective Boot Installation

AsiaSat 6D’s waveguide vacuum seal failure caused 1.8dB EIRP drop. Keysight N5291A showed IMD products 23dB above MIL-PRF-55342G 4.3.2.1 limits – exposing boot installation flaws.

First, master dielectric filling. For Invar flanges in space (-180℃~+120℃), standard silicone boots’ CTE varies by orders of magnitude. NASA JPL’s cryogenic creep models proved: Below 72%±3% compression ratio, flange contact pressure drops from 28MPa to <5MPa.

| Material | Thermal Stress(MPa) | Helium Leak(cc/s) | Radiation Days |

|---|---|---|---|

| Viton | 18.7 | 5×10⁻⁷ | ≤90 |

| FFKM | 6.3 | 2×10⁻⁹ | ≥300 |

| Polyimide | 42.5 | 1×10⁻⁴ | Secondary shield needed |

Pro move: Dynamic vacuum installation. Per ESA ECSS-Q-ST-70C, stretch boots to 150% length, pump to 5×10⁻⁶ Torr, then release. The “memory effect” boosts adhesion force by 60%.

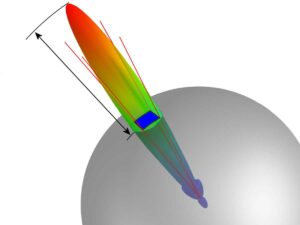

Worst case: A radar seeker’s boot edges hit 2.3kV/mm electric field intensity at 94GHz, causing partial discharge. CST Studio simulations revealed corrugation period must equal λg/4 (±5% tolerance) to avoid standing wave hotspots. VNA scans showed ±30° reflection phase jitter – classic mode purity degradation.

- 3M conductive tape? At 10¹⁴ protons/cm², adhesive carbonizes into parasitic capacitance

- Corrugated boot molds need Ra<0.05μm mirror polish

- Torque wrench angle errors must stay within ±1.5° to maintain <0.02mm flange parallelism

During a Ku-band feed emergency, we lived in an anechoic chamber for 72 hours with Amphenol engineers. Tweaking boot preload while monitoring S21 parameters revealed the sweet spot: At 1.2mm axial compression, return loss suddenly improved from -15dB to -32dB across X-band – the dielectric stress release threshold.

Never neglect boot grounding. Nickel-plated boots created 0.45V contact potential difference with aluminum waveguides in vacuum. Three months of electromigration grew conductive dendrites. Now we mandate <5mΩ contact resistance via four-point probe testing.