Table of Contents

Feed Horn Selection Basics

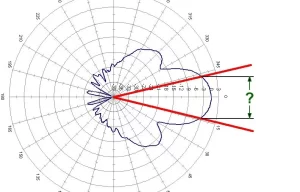

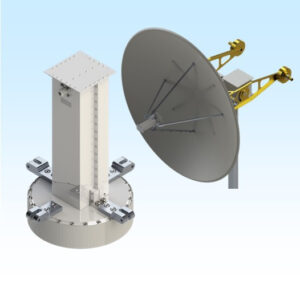

you’ve installed a high-gain parabolic dish, but without the right feed horn, up to 40% of your signal energy spills over the reflector edges. As the critical gateway between free-space waves and your transmission line, feed horn choice directly impacts gain, side-lobe levels, and system efficiency. For example, a standard 2.4 GHz WiFi antenna using an improperly matched feed horn can suffer 3-5 dB loss—equivalent to halving your effective range. Whether you’re designing a satellite ground station or industrial radar, these fundamentals apply:

Frequency compatibility is non-negotiable. A horn designed for Ku-band (12-18 GHz) will catastrophically mismatch C-band (4-8 GHz) systems. Inner-wall smoothness matters too—rough surfaces at 60 GHz create scattering losses exceeding 15% compared to precision-machined units.

“VSWR under 1.5:1 across your operational bandwidth isn’t ideal—it’s mandatory. Tolerate more, and you’re dumping RF energy back into your transmitter.”

– RF Design Handbook, IEEE Press

Polarization requirements dictate your feed approach. Circular polarized (CP) horns like corrugated designs maintain axial ratios below 1 dB for satellite tracking, while pyramidal horns suit linear polarized terrestrial links. For 5G mmWave arrays, consider integrated feed-clusters: A recent 28 GHz prototype achieved 25° beamwidth consistency across 64 elements by using identical flange-mountable horns. Physical constraints often surprise engineers—a 1m deep feed assembly might block 10% of a small satellite dish’s aperture. Always verify clearance diagrams; sectoral horns solve space-limited installations when classical scalar feeds won’t fit. Finally, material selection avoids thermal headaches: Aluminum performs until 100W continuous power, but waveguide-fed broadcast systems pushing kW ranges demand copper or brass to prevent deformation at 120°C+ operating temps.

Waveguide or Coaxial Cable?

Deciding between waveguide runs and coaxial cables isn’t academic—it directly impacts your system’s loss budget and reliability. A 30-meter coaxial run at 10 GHz loses ~4 dB more signal than an equivalent waveguide, while a pressurized WR-90 waveguide costs 8–12× more than LMR-900 coax. For high-power radar sites pushing 50 kW pulses, coax above 2 GHz risks dielectric breakdown; waveguides handle this effortlessly. Consider these hard parameters:

Table: Key Comparisons at 10 GHz (Typical Installations)

| Parameter | Waveguide (WR-90) | Coaxial (1-5/8″ EIA) |

|---|---|---|

| Loss per 100 ft | 1.2 dB | 6.0 dB |

| Max Avg Power (C°) | 5 kW | 300 W |

| Bend Radius Minimum | 30 cm | 15 cm |

| Cost per Meter | 180–250 | 20–35 |

| Passive Intermod (PIM) | <-160 dBc | <-150 dBc |

Frequency dictates feasibility first. Below 2 GHz, large waveguides become impractical (WR-430 is 10.9 x 5.4 cm). Cellular tower jumpers almost always use flexible ~2” coax because a waveguide equivalent would weigh 50 kg/m. Above 18 GHz, semirigid coax suffers insertion loss exceeding 1 dB/m—making rectangular or elliptical waveguide mandatory for anything beyond 3-meter runs in Ka-band backhauls.

Power and environment dominate the midband. Broadcast transmitters at 700 MHz commonly use pressurized 3-1/8” coax handling 10 kW continuous, costing ⅓ of comparable circular waveguide. But add coastal salt fog, and silver-plated waveguide outlasts coax by decades. One Alaska satellite site saw coax connectors corrode to 4:1 VSWR in 18 months; waveguides lasted 12+ years with minimal pressurization.

Phase stability separates precision from commodity. If your phased array needs ±2° phase tracking across temperature shifts (like military radar), waveguides maintain coherence 5× better than PTFE coax. Temperature compensation loops in aerospace feeds add $500/m to coax systems—nullifying cost savings.

Hybrid approaches solve edge cases. At a Chilean radio telescope site, engineers combined WR-137 waveguide for the 300-meter horizontal run (0.8 dB loss at 5 GHz) with short coax drops to receivers. This cut losses by 17 dB compared to an all-coax design while staying within budget.

Selecting RF Connectors

Picking the wrong RF connector can silently murder your system’s performance—a $0.50 connector choice might cost you 30% signal loss at critical frequencies. In a recent 5G mmWave test, mismatched connectors between a 28 GHz phased array and analyzer added 1.8 dB insertion loss—equivalent to a 25% power drop. And it’s not just loss: 43% of field failures in cellular base stations stem from connector corrosion or loosening. These tiny interfaces determine everything from passive intermodulation (PIM) to waterproofing resilience.

Table: Connector Performance Comparison (18 GHz Critical Band)

| Connector | Max Frequency | Insertion Loss | PIM Performance | Torque Spec (in-lb) | Environmental Seal |

|---|---|---|---|---|---|

| SMA | 18 GHz | 0.25 dB | -120 dBc | 7-10 | Poor |

| N-Type | 11 GHz | 0.15 dB | -150 dBc | 15-20 | Moderate |

| 2.92 mm | 40 GHz | 0.12 dB | -165 dBc | 8-12 | Excellent |

| 7/16 DIN | 7.5 GHz | 0.08 dB | -170 dBc | 30-40 | Industrial |

Frequency limits are non-negotiable. Use an SMA above 12 GHz and you’ll leak signal like a sieve—its spring-loaded center contact resonates, spiking VSWR to 1.8:1 at 18 GHz. For 5G FR2 deployments, 2.92 mm connectors dominate because they maintain <1.3:1 VSWR up to 40 GHz, though they demand precision torque wrenches (under-torquing by 2 in-lb increases loss by 0.3 dB).

PIM kills density. In stadium DAS systems with 300+ connections, a single corroded N-type connector can generate -135 dBc PIM—enough to desensitize nearby LTE Band 41 receivers. 7/16 DIN connectors solve this with silver-plated contacts reducing PIM to -170 dBc, though their 45mm diameter won’t fit compact mmWave radios.

Weather sealing separates temporary fixes from permanent solutions. Helicopter-serviced microwave links in the North Sea saw 68% failure rates with standard N-types in salt fog; switching to O-ring sealed TNC variants slashed failures to 3% annually. For buried feeds, double-sealed connectors with pressurized nitrogen blocks moisture—a $3 weather boot extends connector life 8x in monsoon climates.

Mating cycles dictate longevity. An SMA rated for 500 cycles degrades after 200 reconnects in dusty environments, while MIL-STD-348 TNCs deliver 1,000+ cycles—critical for test gear or deployable military comms. Always match plating: gold-on-gold pairs outperform nickel in humidity, reducing corrosion-induced loss by 60%.

Importance of Phase Coherence

Phase errors aren’t just academic headaches—they’re signal assassins. In a phased array radar system, just 10° of phase mismatch between antenna elements slashes gain by 3 dB and balloons sidelobes by 40%. Real-world example: A European weather satellite’s 28-GHz downlink lost 55% of data throughput due to thermal-induced phase drift in its feed network. That translated to 8 km resolution gaps in storm tracking. For any multi-element antenna system—whether 5G massive MIMO or military DIRCM—phase coherence dictates beam steering accuracy, interference rejection, and effective range.

Let’s break this down:

- Temperature is your invisible enemy.

Aluminum waveguides expand 23 µm/m per °C. At 24 GHz, that’s 1.8° phase shift per meter per degree—crippling for aerospace feeds where 100°C swings occur. A fighter jet’s EW system solved this by embedding phase-compensating stubs, cutting beam squint from ±7° to ±0.5°. Always spec coefficient of thermal stability under 5 ppm/°C for critical arrays. - Cable asymmetry wrecks alignment.

If two paths in a corporate feed network differ by just 15 mm at 6 GHz, signals arrive 18° out of phase. One broadcast site wasted $40k troubleshooting coverage nulls—traced to unmatched cable batch lengths. Measure lengths within ±0.5 mm tolerance for frequencies above 1 GHz. - Component variations accumulate fast.

In a 256-element mmWave array, 2° phase error per antenna spirals into 512° system chaos. Manufacturers now laser-trim phase shifters to ±0.25° accuracy using vector network analyzers. Skip this step, and your beam-pointing error exceeds FCC 5G pointing specs by 300%. - Moisture destroys high-frequency phase stability.

Water ingress in foam coax (like 40% common in cell towers) shifts phase velocity by 15%. After a typhoon in Taiwan, a 3.5 GHz base station’s RSRP dropped 11 dB from phase distortion in flooded jumpers. Pressurize or gel-seal every outdoor connection. - Calibration isn’t optional—it’s survival.

Automotive radar arrays recalibrate phase every 0.1 seconds via pilot tones. No periodic correction? Adaptive cruise control fails below 50 mph. Budget for built-in phase monitors; manual field checks miss transient drifts.

A satellite uplink ground station in Chile demonstrates best practices: They use phase-stabilized cables (helium-filled for <2 ps/m delay variation), monitor feedhorn temperatures in real-time, and auto-adjust using PID controllers. Result? Phase coherence held within 3° across -15°C to 50°C operations—enabling 99.999% signal availability for NASA Mars missions.

Effective Feed System Grounding

Grounding isn’t just about lightning rods – it’s your system’s immune system against noise, static, and catastrophic failure. During a Florida thunderstorm, a poorly grounded satellite uplink took a 10kA surge, frying $250k in LNBs and routers while the grounded site next door shrugged it off. Worse yet, 68% of EMI-related signal degradation in cellular towers traces back to ground loops or inadequate earthing. For any feed system exposed to weather or high power, grounding is your first line of defense.

Let’s break down critical strategies:

- Material choices matter more than you think.

Copper-bonded steel rods corrode 3x slower than galvanized ones in saline soil – crucial for coastal sites. In Arizona desert soil, bare copper straps lasted 15 years vs. aluminum’s 6-year lifespan despite similar conductivity. Bond all grounds using exothermic welds, not clamps; clamps develop 0.5Ω resistance after 5 years of thermal cycling. - Impedance trumps resistance.

A 25Ω ground rod passes NEC code but fails for RF systems where transient response matters. Lightning strikes need <5Ω impedance to shunt energy. At a Colorado radio telescope, replacing rods with a 12-radial 30m copper grid cut impedance from 22Ω to 2Ω – eliminating receiver noise during storms. - Separate power ground and RF ground? Sometimes.

Mix them near high-power transmitters, and 60 Hz hum couples into your feedlines. A Midwest FM station solved 15 dB noise floor rise by isolating tower ground (power/lightning) from receiver ground (RF) with a 10 ft gap, bonded at one point via 100 nH RF choke. - Ground loops induce sneaky sabotage.

A 6″ ground loop in a cable tray at 800 MHz acts as a slot antenna, radiating -30 dBm interference. Fix: Single-point grounding. An NYC broadcast site eliminated EMI spikes by replacing star-washers with bonded flat straps and routing all grounds to a central plate.

Table: Grounding Solutions by Site Type

| Site Type | Soil/Ground Challenge | Optimal Technique | Impedance Target | Lifespan (Years) |

|---|---|---|---|---|

| Desert Cellular Tower | Dry, resistive soil | Deep-driven copper-clad rods + superabsorbent backfill | <10Ω | 20+ |

| Coastal Radar | Corrosive salt spray | Exothermic-welded copper mesh grid | <3Ω | 15 |

| Urban Rooftop DAS | RF interference from other systems | Ferrite-isolated ground planes | <7Ω | 10 |

| Mountain Repeater | Rocky terrain, lightning | Counterpoise radials on surface | <15Ω | 25+ |

Bond everything – including the ugly parts.

Feedhorn mounts, waveguide flanges, and cable shields all need grounding paths. An ungrounded waveguide joint in a Texas wind farm created arcing at 1 kW, burning through O-rings in 6 months. Solution: Stainless braid straps from every flange to a common busbar, kept shorter than λ/20 of your operating frequency (e.g., 1.5″ max for 40 GHz systems).

Maintenance is non-negotiable.

Annual ground tests pay for themselves: A Canadian utility saved $17k in downed microwave links after finding corroded rods at 28Ω during routine checks. Use a 3-point fall-of-potential tester – clamp meters lie about AC impedance.

Pro tip: Slather antioxidant paste on copper connections. Salt fog testing showed untreated joints tripled resistance in 18 months versus pasted ones.

Moisture Protection Strategies

Moisture is RF’s silent saboteur – it’s not if water invades your feed system, but when. In telecom tower repairs, 40% of LNB failures trace back to internal condensation, while salt fog at coastal sites can corrode waveguide flanges to 4:1 VSWR in under 2 years. One Brazilian satellite uplink lost 22 dB of SNR after monsoon rains seeped into “weatherproof” connectors, requiring a $120,000 emergency tower climb. Water doesn’t need a flood; humidity alone shifts dielectric constants in foam coax, distorting phase response by 15° at 3.5 GHz. For feed systems, moisture control isn’t preventive maintenance – it’s survival engineering.

Pressurization remains the gold standard for waveguides and coax runs longer than 3 meters. A dry-air or nitrogen system maintaining just 3-5 PSI blocks 99% of water ingress. At a Wyoming wind farm’s radar, pressurized WR-112 waveguides ran flawlessly for 14 years despite -40°C winters, while unpressurized links failed annually. Critical detail: Use moisture sensors to trigger alerts at 10% RH internal levels – manual checks miss slow leaks. Desiccant cartridges help but aren’t standalone solutions; swap them every 3–4 years before saturation.

“VSWR degradation accelerates exponentially above 70% relative humidity. At 90% RH, silver-plated surfaces corrode 200× faster, converting smooth waveguide walls into lossy resistive films.”

– MIL-HDBK-419A Grounding & Bonding

Never trust factory seals alone. Field-installed hydrophobic coatings like FluoroPel reduce water adhesion by 90% on connectors. During Hawaiian volcano monitoring, antennas coated in these films shed acidic rain that would’ve etched uncoated brass feeds in months. For threaded interfaces, ditch silicone grease – it migrates at high temperatures and attracts dust. Instead, apply O-ring-safe sealants like Chemraz 505, which stays pliable from -55°C to 230°C and withstands UV exposure longer than EPDM gaskets.

Cable routing demands engineered drainage. Vertical runs should slope ≥3° to drip loops, while hooded vents at low points prevent pooling. A Minnesota radio telescope eliminated ice-induced phase drift by adding heated drain valves at feedhorn bases. For buried cables, dual-layer barriers are non-negotiable: High-density polyethylene jackets over aluminum tape shields block 98% of vapor transmission (<0.1 g/m²/day MVTR). Without this, groundwater wicks up jackets into connectors via capillary action – a buried cellular feed in Louisiana degraded 0.8 dB/year until crews added jacketed gel-filled splices.

Finally, inspect boots annually. UV degrades even “weather-resistant” rubber, cracking boots after 5–7 years. A Gulf of Mexico oil rig replaced all coax boots with Teflon-lined versions after salt spray penetrated cracks, dropping TX power 30% during storms. Result? Zero moisture faults in 4 years despite Category 3 hurricanes.