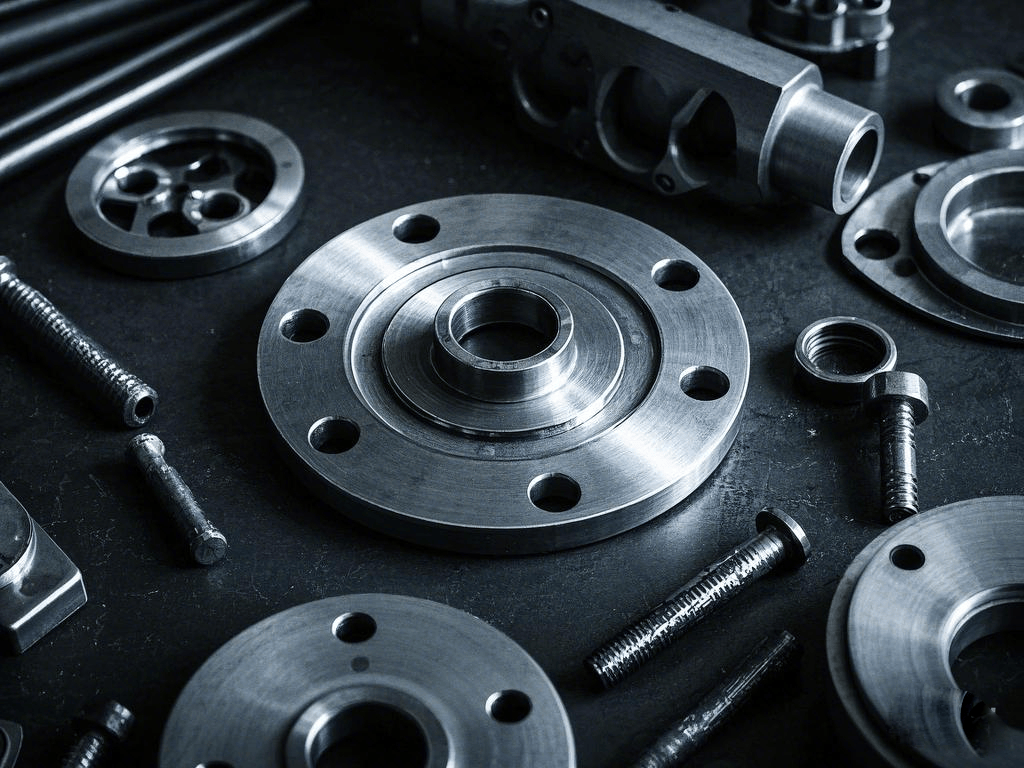

Why Material Choice Matters for Flange Shims

Material choice for flange shims affects sealing performance, corrosion resistance, and durability. Stainless steel (e.g., 316 SS) offers high strength and withstands temperatures up to 800°F, while PTFE provides chemical resistance. Proper selection ensures compliance with standards like ASTM F916 and prevents leaks or equipment failure. Metal vs Plastic Showdown Last year, the Zhongxing 9B […]

Why Material Choice Matters for Flange Shims Read More »