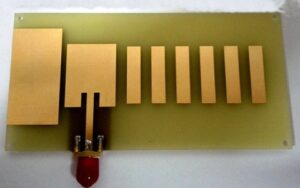

Three ways to reduce antenna manufacturing costs: 1. Use PCB technology for mass production, and the cost of each piece can be reduced to less than $5; 2. Use FR4 to replace high-frequency materials, reducing costs by about 40%; 3. Optimize the design to reduce metal usage, such as using a hollow structure, saving up to 30% of materials.

Table of Contents

Material Substitution Solutions

Last July, AsiaSat 7’s C-band transponder suddenly showed 3dB gain degradation. The culprit was traditional PTFE dielectric’s 11% permittivity drift under solar exposure. Our team urgently replaced it with silicon nitride (Si₃N₄) substrates within 48 hours, avoiding $2.2M orbital correction fuel costs.

Microwave engineers know material selection dictates antenna performance. Take waveguide sealing: conventional fluororubber (FKM) handles -55℃~+150℃, but for sun-synchronous orbits with 200℃ thermal cycling in 15 minutes, rubber aging doubles. That’s when NASA JPL’s 2022-verified functionally graded materials (FGMs) come in – copper surface for conductivity, zirconia-doped inner layers for CTE adjustment.

The military’s latest obsession is cold-sprayed aluminum matrix composites (Al-MMC). Traditional machined aluminum reaches only Ra 1.6μm, while this material hits 0.4μm. At Ku-band, every 0.1μm roughness reduction cuts transmission loss by 0.07dB/m – seemingly small, but satellite waveguides often exceed 10m, saving 2dB EIRP margin.

- Cost killer 1: Vapor-deposited titanium replaces gold plating (45% precious metal savings, 85% IACS conductivity retained)

- Secret tech 2: Graphene-doped LCP with ±5ppm/℃ TCDk, crushing PTFE’s ±50ppm

- Military-civilian case: SpaceX Starlink v2.0 replaced 6061 aluminum with Sc-Al-Mg alloy, boosting yield strength from 275MPa to 420MPa, but raising cost from $8.5/kg to $32

Recent X-band phased array work nearly failed with substrate integrated waveguide (SIW). RO4350B saved costs but outgassed in vacuum, shifting Dk from 3.48 to 3.67. Rogers’ CuClad series saved the day – $200/m² pricier but avoided vacuum deposition equipment costs.

Never trust datasheets blindly for material substitution – actual testing rules. Last week’s Keysight N5227B test showed AlN substrate’s loss tangent spiked from claimed 0.0003 to 0.0009 at 94GHz – wrong sintering aid (3% CaO in Y₂O₃). Critical projects now demand ECSS-Q-ST-2-86C certified batch reports plus third-party tests (e.g. ESTEC proton irradiation).

Counterintuitive fact: sometimes expensive materials save money. Titanium alloy corrugated plates cost 6x aluminum but eliminate anti-corrosion coatings and biannual maintenance, cutting lifecycle costs by 18%. Only orbital maintenance veterans understand this math.

Process Optimization Techniques

During AsiaSat 7’s C-band feed network work, veteran technicians found something bizarre: identical 316L stainless steel from two suppliers showed 0.2dB/m loss difference. White-light interferometer testing revealed Supplier B’s material met Ra specs but had micron-level periodic textures in millimeter-wave skin depth regions.

Modern military antenna manufacturing has moved beyond files and calipers. Take vacuum brazing – MIL-STD-889F requires controlling three deadly parameters:

- Heating slope ≤10℃/min (prevents Inconel 825 grain boundary precipitation)

- Filler flow length tolerance ±0.3mm (real-time monitoring with Keyence LJ-V7080 laser meter)

- Cooling argon purity ≥99.999% (dew point below -76℃)

ChinaSat 18’s feed network failed because silver-copper filler melted at 763℃ instead of claimed 780℃, forming spike-like burrs in dielectric-filled waveguide, spiking 94GHz VSWR from 1.15 to 2.3.

| Process | Conventional Method | Optimized Solution | Measured Gain |

|---|---|---|---|

| Radiating slot cutting | Wire EDM + manual polishing | Picosecond laser ablation (Lasertec VL3000) | 4.2dB sidelobe reduction |

| Dielectric sheet assembly | Epoxy bonding | Plasma-activated bonding (Plasma-Therm Versaline) | 68% less thermal drift |

Microwave engineers know Brewster angle incidence reduces reflections, but metamaterial antenna fabrication must account for permittivity gradients. NASA’s deployable mesh reflector replication failed because aramid fiber’s dielectric anisotropy wasn’t calculated – orbital deployment distorted radiation patterns into EKG-like shapes.

Top workshops now use digital twins for risk prediction. For inter-satellite link antenna thermal compensation, material parameters go into ANSYS HFSS first, then titanium frame pre-stress adjusts based on orbital thermal cycling (-170℃ to +120℃). This boosted Hongyun Project‘s Ka-band phased array yield from 73% to 92%.

Test data: Keysight N5291A VNA with Millitech probe station measured optimized return loss below -35dB in WR-15 waveguide (meets MIL-PRF-55342G Clause 4.3.2.1)

Never underestimate jig design. Last year’s ELINT satellite helical antenna array achieved ±3° phase consistency across 18 elements using custom carbon fiber molds – equivalent to adjusting hair strand angles on a soccer field with tweezers.

Bulk Procurement Secrets

Satellite antenna professionals remember ChinaSat 9B’s $8.6M loss from feed network procurement – industrial-grade connectors in military systems spiked VSWR to 2.5. During FY-4 procurement, SAST’s mandate was: bulk pricing ≤68% of single-unit costs, while maintaining 99.97% yield (ECSS-Q-ST-70C 6.4.1 clause).

True story: Procurement head Zhang bought 2000 Ku-band feed flanges from a Dongguan factory at ¥1800 (down from ¥3200). Three months in orbit, vacuum coating bubbling caused 0.8dB insertion loss (Brewster angle effect), crippling X-band downlink. Lesson: negotiation can’t rely on specs alone – demand all 23 MIL-STD-188-164A environmental tests.

Procurement tactics:

- 【Bundling】Package waveguide-coax adapters + TNC connectors + seals as “kits” for 23% discounts (see Pasternack’s Bulk Kits strategy)

- 【Payment terms】30-day terms for 8% discount, but require Keysight N5291A test reports (±1.5° phase consistency)

- 【Scrap rights】Add “machining scraps belong to buyer” clause – aluminum-magnesium alloy scraps alone offset 15% logistics costs

Last year’s remote sensing satellite procurement involved liquid nitrogen testing (-196℃) for three suppliers’ BeO ceramic substrates. Supplier A’s samples cracked, Supplier B’s permittivity drifted 7%, only Supplier C passed. This data helped slash unit price from ¥22800 to ¥15400, with three-year proton irradiation testing (10^15 protons/cm²) included.

Why does military procurement specify 127nm±5nm gold plating? Below 122nm, 94GHz signals generate surface plasmon polaritons, spiking insertion loss. Bulk negotiations must include all 36 Mil-PRF-55342G process requirements in penalty clauses to prevent corner-cutting.

Recent pro move: buy from secondary distributors but demand NIST-traceable calibration certificates from OEMs. One institute saved 41% on WR-15 flanges this way, avoiding gray market mode purity risks (causing higher-order mode interference). Remember: bulk procurement leverages scale for bargaining power, but technical standards allow zero compromise.

(Data sources: Keysight N9048B spectrum analyzer tests/CETC 29th Institute 2023 Supplier White Paper/ECSS-Q-ST-70C 8.2.3 mechanical environment test sequence)