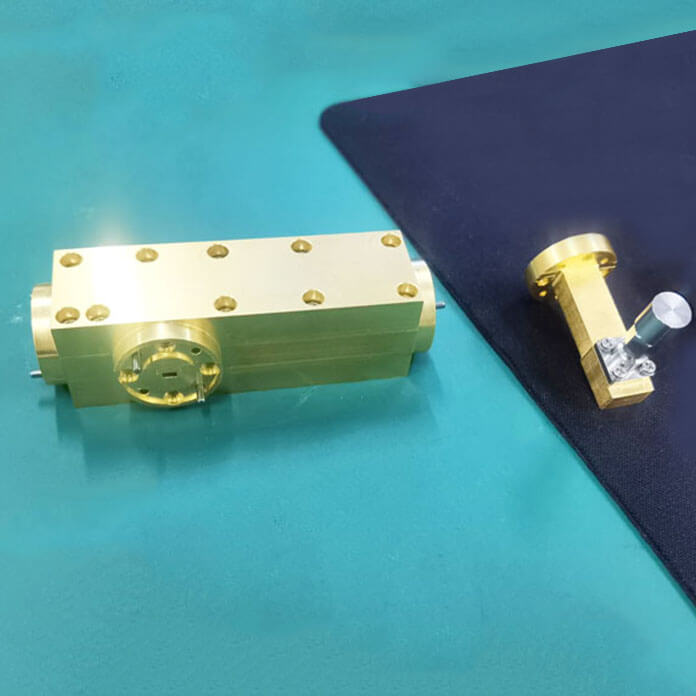

Waveguide Pressure Windows

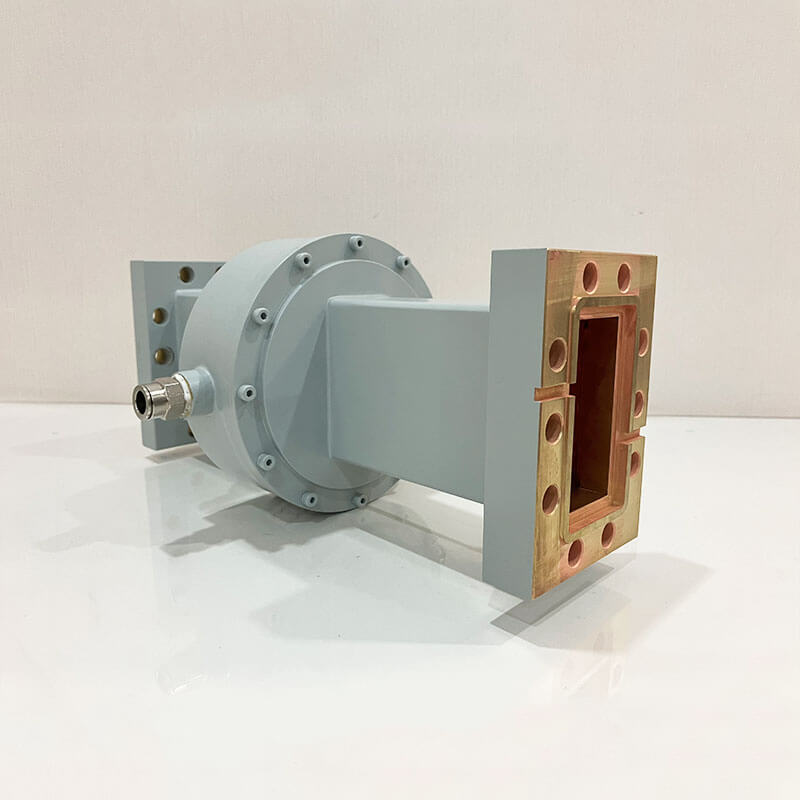

Waveguide pressure windows are critical components designed to seal waveguide systems while allowing electromagnetic signals to pass through with minimal attenuation. They are used to maintain pressure differentials and prevent environmental contaminants from entering the system, essential in applications such as radar, satellite communications, and research facilities, ensuring system integrity and performance.

Dolph Microwave’s line of waveguide pressure windows is expertly designed to maintain the integrity and performance of waveguide systems across a broad frequency range. These essential components provide a robust seal against environmental contaminants while allowing microwave energy to pass with minimal loss, ensuring system reliability and efficiency in a variety of demanding applications.

Key Features

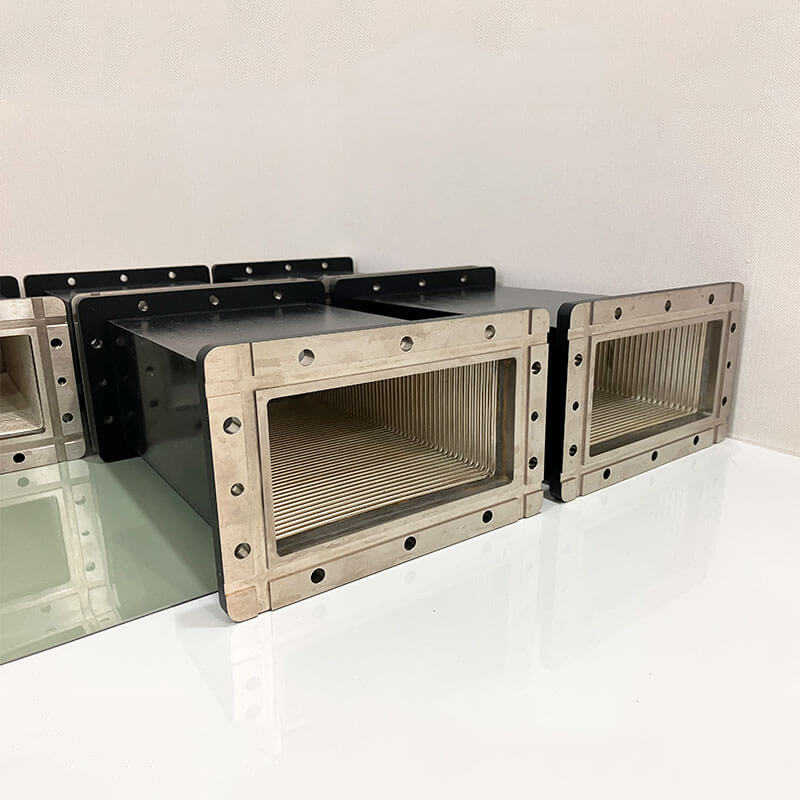

Broad Frequency and Size Range

- Frequency Operation: Spanning from 0.32 to 112 GHz, compatible with a wide array of system requirements.

- Waveguide Size Compatibility: From WR-2300 to WR-10, accommodating the standard rectangular waveguide range from BJ3 to BJ900.

Exceptional Performance

- Low VSWR and Insertion Loss: Featuring a maximum VSWR of 1.2:1 and a typical insertion loss of 0.2 dB over the full waveguide bandwidth, optimizing signal integrity.

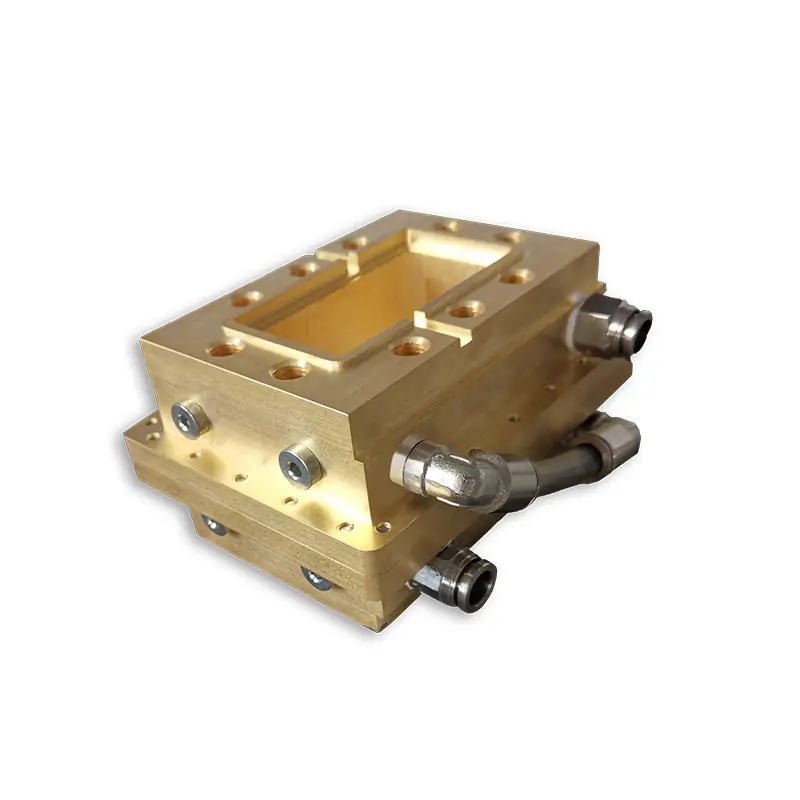

Durable Materials and Construction

- Window Materials: Utilizing Cooper-Clad / Teflon-Fiberglass to ensure optimal microwave transmission and environmental sealing.

- Build Quality: Constructed from Oxygen Free Hard Copper or Copper Alloy, guaranteeing durability and resistance to corrosion.

High Pressurization Capability

- Pressure Resistance: Designed to efficiently seal at pressures as high as 70 psi, suitable for military and other severe environmental conditions.

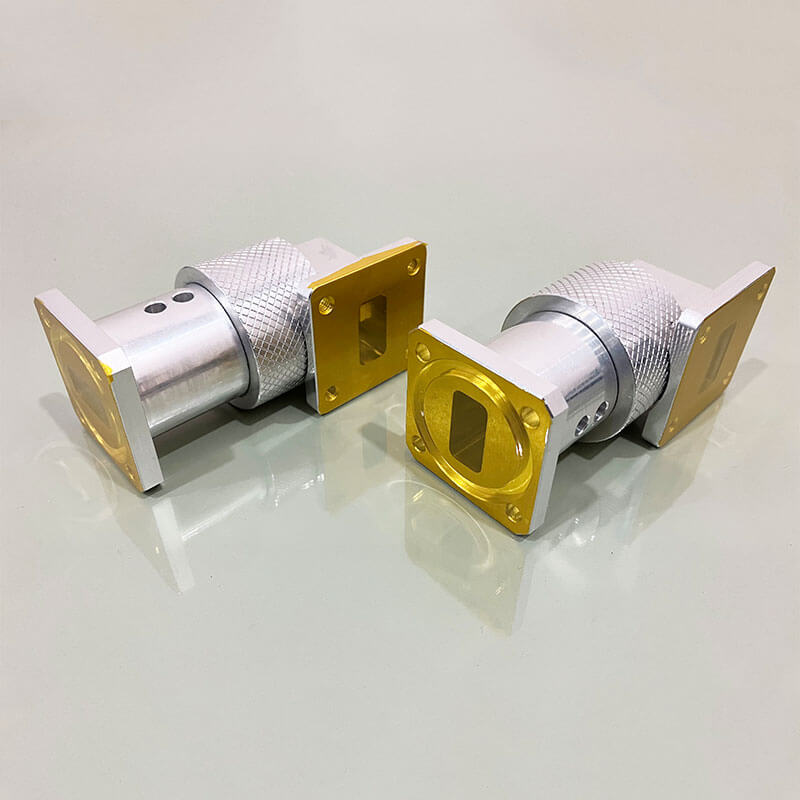

Precision Engineering

- Machining Accuracy: Precision machining ensures the components fit perfectly, maintaining accurate and lasting performance.

Applications

Waveguide pressure windows from Dolph Microwave are indispensable in various sectors:

- Radar Systems: Protecting radar waveguides from environmental conditions while ensuring precise signal transmission.

- Satellite Communications: Securing communication links by isolating sensitive components from external elements.

- Military Applications: Providing robust environmental isolation in systems exposed to harsh conditions.

- Telecommunications: Enhancing the reliability of microwave links by preventing moisture and contaminant ingress.

- Research and Testing Facilities: Ensuring accurate measurements in controlled environments, free from dust and moisture.

Product Specifications Example

Here’s an example specification table for our waveguide pressure windows:

| Specification | Detail |

|---|---|

| Frequency Range | 0.32 to 112 GHz |

| Waveguide Sizes | WR-2300 to WR-10 |

| VSWR | Max 1.2:1 |

| Insertion Loss | Typical 0.2 dB |

| Material | Cooper-Clad / Teflon-Fiberglass |

| Flange Type | Cover, Standard; Choke available |

| Construction | Oxygen Free Hard Copper/Copper Alloy |

Dolph Microwave is committed to delivering high-quality waveguide solutions that meet the precise needs of our clients. Whether for standard or customized configurations, our waveguide pressure windows are designed to provide reliable and efficient performance for any application.

Custom Solutions and Expert Support

We understand the unique challenges of each project and offer custom solutions tailored to your specific requirements. Our team of experienced engineers is ready to assist with selecting the right components for your application, ensuring seamless integration and optimal system performance.

For more information or to discuss your specific needs, please contact us. Dolph Microwave is your trusted partner for advanced waveguide technology solutions, driving your projects to success with precision-engineered components.

| MODEL | FREQ. RANGE (GHz) | WG SIZE | VSWR Max. | PRESSURE (PSIG) | AVG POWER (W) | WINDOW MATERIAL | FLANGE TYPE | MATERAL | FINISH | DATASHEET | ||

| COVER | GROOVED | |||||||||||

| DH-9WAL… | 0.76-1.15 | WR975 | 1.15:1 | Up to 45 | Up to 3000 | Teflon/Fiberglass/Ceramics | UDR9 | PDR9 | Al | Chromate | STEP | |

| DH-12WAL… | 0.96-1.46 | WR770 | 1.15:1 | Up to 45 | Up to 3000 | Teflon/Fiberglass/Ceramics | UDR12 | PDR12 | Al | Chromate | STEP | |

| DH-14WAL… | 1.13-1.73 | WR650 | 1.15:1 | Up to 45 | Up to 1000 | Teflon/Fiberglass/Ceramics | UDR14 | PDR14 | Al | Chromate | STEP | |

| DH-18WAL… | 1.45-2.2 | WR510 | 1.15:1 | Up to 45 | Up to 1000 | Teflon/Fiberglass/Ceramics | UDR18 | PDR18 | Al | Chromate | STEP | |

| DH-22WAL… | 1.72-2.61 | WR430 | 1.15:1 | Up to 45 | Up to 1000 | Teflon/Fiberglass/Ceramics | UDR22 | PDR22 | Al | Chromate | STEP | |

| DH-26WAL… | 2.17-3.3 | WR340 | 1.15:1 | Up to 45 | Up to 1000 | Teflon/Fiberglass/Ceramics | UDR26 | PDR26 | Al | Chromate | STEP | |

| DH-32WAL… | 2.6-3.95 | WR284 | 1.15:1 | Up to 45 | Up to 1000 | Teflon/Fiberglass/Ceramics | UDR32 | PDR32 | Al/Cu | Chromate | STEP | |

| DH-40WAL… | 3.22-4.9 | WR229 | 1.15:1 | Up to 45 | Up to 1000 | Teflon/Fiberglass/Ceramics | UDR40 | PDR40 | Al/Cu | Chromate | STEP | |

| DH-48WAL… | 3.94-5.99 | WR187 | 1.15:1 | Up to 45 | Up to 1000 | Teflon/Fiberglass/Ceramics | UDR48 | PDR348 | Al/Cu | Chromate | STEP | |

| DH-58WAL… | 4.64-7.05 | WR159 | 1.15:1 | Up to 45 | Up to 1000 | Teflon/Fiberglass/Ceramics | UDR58 | PDR58 | Al/Cu | Chromate | STEP | |

| DH-70WAL… | 5.38-8.17 | WR137 | 1.15:1 | Up to 45 | Up to 1000 | Teflon/Fiberglass/Ceramics | UDR70 | PDR70 | Al/Cu | Chromate | STEP | |

| DH-84WAL… | 6.57-9.99 | WR112 | 1.15:1 | Up to 45 | Up to 1000 | Teflon/Fiberglass/Ceramics | UDR84/UBR84 | PDR84/PBR84 | Al/Cu | Chromate | STEP | |

| DH-100WAL… | 8.2-12.5 | WR90 | 1.15:1 | Up to 45 | Up to 1000 | Teflon/Fiberglass/Ceramics | UDR100/UBR100 | PDR100/PBR100 | Al/Cu | Chromate | STEP | |

| DH-120WAL… | 9.84-15 | WR75 | 1.15:1 | Up to 45 | Up to 800 | Teflon/Fiberglass/Ceramics | UBR120 | PBR120 | Al/Cu | Chromate | STEP | |

| DH-140WAL… | 11.9-18 | WR62 | 1.15:1 | Up to 45 | Up to 800 | Teflon/Fiberglass/Ceramics | UBR140 | PBR140 | Al/Cu | Chromate | STEP | |

| DH-180WAL… | 14.5-22 | WR51 | 1.15:1 | Up to 45 | Up to 800 | Teflon/Fiberglass/Ceramics | UBR180 | PBR180 | Al/Cu | Chromate | STEP | |

| DH-220WAL… | 17.6-26.7 | WR42 | 1.15:1 | Up to 45 | Up to 800 | Teflon/Fiberglass/Ceramics | UBR220 | PBR220 | Al/Cu | Chromate | STEP | |

| DH-260WAL… | 21.7-33 | WR34 | 1.15:1 | Up to 45 | Up to 500 | Teflon/Fiberglass/Ceramics | UBR260 | PBR260 | Al/Cu | Chromate | STEP | |

| DH-320WAL… | 26.3-40 | WR28 | 1.15:1 | Up to 45 | Up to 500 | Teflon/Fiberglass/Ceramics | UBR320 | PBR320 | Al/Cu | Chromate | STEP | |

| DH-400WAL… | 32.9-50.1 | WR22 | 1.15:1 | Up to 45 | Up to 100 | Teflon/Fiberglass/Ceramics | FUGP400/UG-383U/M | Al/Cu | Chromate | STEP | ||

| DH-500WAL… | 39.2-59.6 | WR19 | 1.15:1 | Up to 45 | Up to 100 | Teflon/Fiberglass/Ceramics | FUGP500/UG-383U/M | Al/Cu | Chromate | STEP | ||

| DH-620WAL… | 49.8-75.8 | WR15 | 1.15:1 | Up to 45 | Up to 100 | Teflon/Fiberglass/Ceramics | FUGP620/UG-385U/M | Al/Cu | Chromate | STEP | ||

| DH-740WAL… | 60.5-91.9 | WR12 | 1.15:1 | Up to 45 | Up to 100 | Teflon/Fiberglass/Ceramics | FUGP740/UG-387U/M | Al/Cu | Chromate | STEP | ||

| DH-900WAL… | 73.8-112 | WR10 | 1.15:1 | Up to 45 | Up to 100 | Teflon/Fiberglass/Ceramics | FUGP900/UG-387U/M | Al/Cu | Chromate | STEP | ||

| Part Number Guide: DH-100WPW10PMA600 "100"—Waveguide Size | WR90 "WPW"—Waveguide Type | Waveguide Pressure Windows "10"—Thickness | 10 mm "P"— Flange Type | Rectangular Flat "M"— Flange Type | Rectangular Grooved "A/C"— Material | Aluminium, Cu "600"— Handling Power | 600 W CW. |

||||||||||||

| Note: All Dolph-MW models include an surtec/corrosion protection treatment and are painted flat black. Flanges are unplated, polished and surtec. Other finishes and paint colors are available upon request. |

||||||||||||